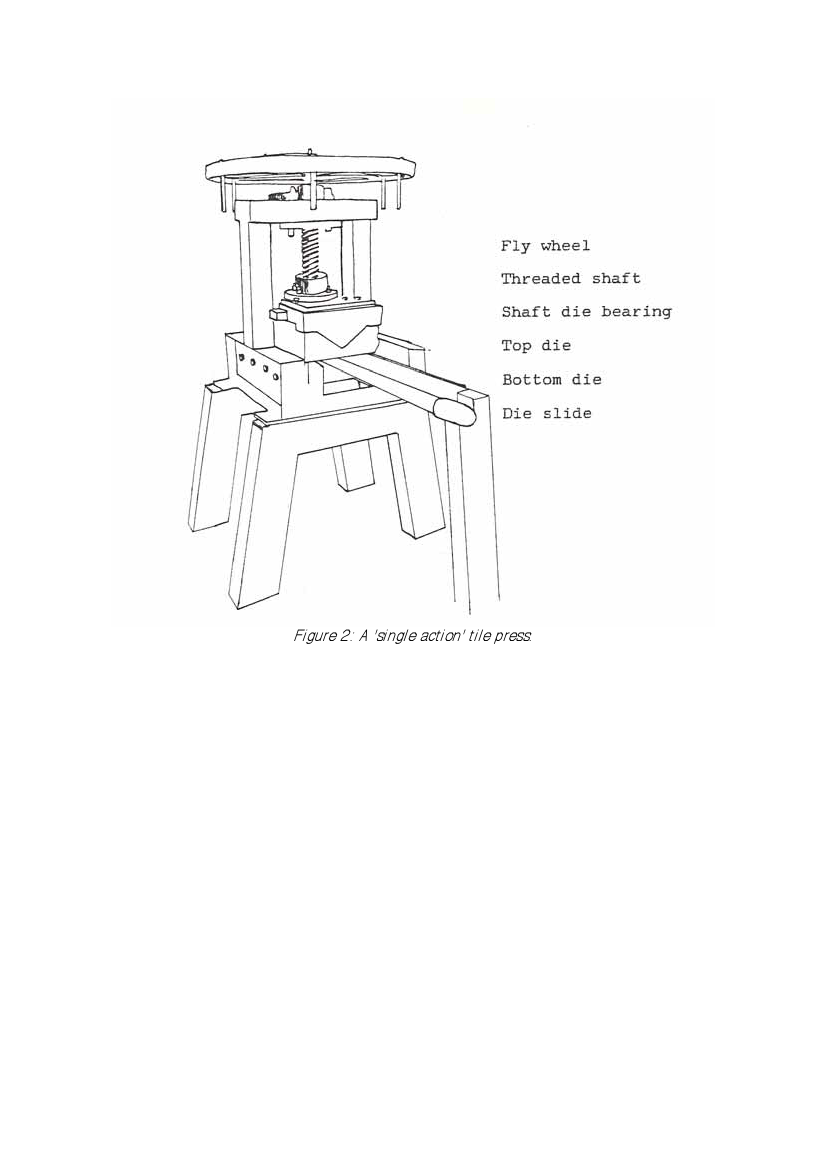

Figure 2: A 'single action' tile press.

Greatest flexibility is provided using a 'double action' (figure 1) press for high demand flat

roof tiles with a 'single action' (figure 2) press for ridge tiles. By double action we mean that

there are two lower dies, so while one die is being emptied of a finished tile and loaded with

clay, the other die is being pressed. The double action press gives a great range of production

levels as it can easily be used as a single action press if the factory needs to operate at low

capacity, while its peak production rate is twice that of a single action press with very little

additional cost. Its peak production (12 tiles per minute can be expected) is only eight per

cent less than a modern, expensive electric revolver press!